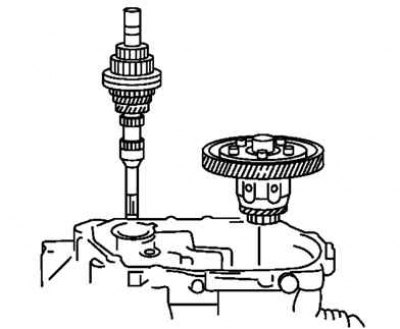

Pic. 3.67. Installation of input shaft and differential shaft

Install the final drive housing and tighten the input shaft fasteners to the specified torque (pic. 3.67).

Tightening torque: 37.3 - 52.0 Nm.

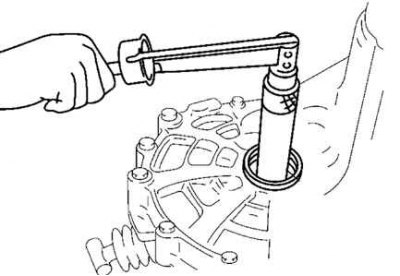

Pic. 3.68. Measuring differential shaft load with a torque wrench

Install special tool and dynamometer or torque wrench (pic. 3.68).

Make sure the preload is within the correct range.

If this is not the case, repeat the operations, starting with the adjustment of the preload in the bearings.

- Preload: 1.4 - 1.9 Nm.

- Dynamometer readings: 14–19 N.

Remove the special tool.

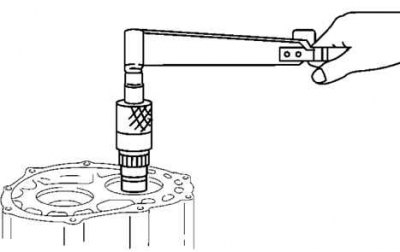

Pic. 3.69. Input shaft load measurement with a torque wrench

Establish a transmission in the block with the main transfer, as it is shown in drawing 3.69, establish the special adaptation on an input shaft.

Make sure the preload is within the correct range.

If this is not the case, repeat the operations, starting with the adjustment of the preload in the bearings.

- Preload: 0.12 - 0.39 Nm.

- Dynamometer readings: 1.2–3.9 N.

Remove the special tool, final drive housing, input shaft and differential.

Install the output shaft and final drive housing, tighten the fasteners to the rated torque.

Tightening torque: 37.3 - 52.0 Nm.

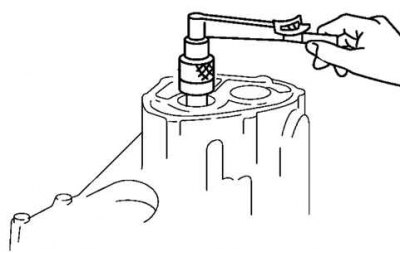

Pic. 3.70. Output shaft load measurement with a torque wrench

Install special tool and dynamometer or torque wrench (pic. 3.70).

Make sure the preload is within the correct range.

If this is not the case, repeat the operations starting with adjusting the preload in the bearings.

- Preload: 0.2–0.3 Nm.

- Dynamometer readings: 2–3 N.

Remove the special tool and the final drive housing.